Innovative Solutions for Battery Factory Efficiency and Sustainability

The global shift towards electric vehicles (EVs) and renewable energy storage has amplified the demand for efficient and sustainable practices in Battery Factories. According to a report by the International Energy Agency (IEA), the global market for batteries is expected to reach $140 billion by 2027, driven largely by advancements in technology and the increasing adoption of green energy solutions. As Battery Factories strive to meet these soaring demands, innovative solutions that enhance operational efficiency while minimizing environmental impact are becoming essential.

From smart manufacturing techniques leveraging IoT and AI to cleaner production methods, the industry's focus on sustainability is not just a trend but a necessity for long-term success. In this blog, we will explore cutting-edge strategies and technologies that are reshaping Battery Factory operations, ensuring both productivity and ecological responsibility in an ever-evolving landscape.

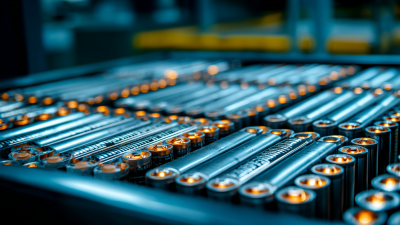

Innovative Automation Technologies Boosting Battery Production Efficiency

Innovative automation technologies are transforming battery production efficiency, addressing the growing demand for sustainable energy solutions. According to a recent report by the International Energy Agency (IEA), global battery manufacturing capacity is projected to increase by nearly 60% annually through 2030. This surge necessitates advanced automation systems that can optimize production processes while minimizing environmental impact. Integrated robotics and AI-driven analytics are now crucial in streamlining operations and reducing waste.

With an emphasis on Industry 4.0, many battery manufacturers are adopting smart technologies to enhance operational efficiency. Studies have shown that implementing automated systems can lead to a reduction in production cycle time by up to 30%. For instance, automated quality control machines, equipped with machine vision technology, can detect defects in real-time, ensuring higher product reliability. The deployment of IoT sensors further allows for predictive maintenance, reducing downtime and contributing to a more sustainable production cycle by avoiding unnecessary resource consumption. As these innovative automation technologies continue to evolve, they hold the key to meeting the rising energy storage demands while fostering an eco-friendly future for the battery industry.

Sustainable Materials: Driving Eco-Friendly Practices in Battery Manufacturing

In recent years, the increasing demand for electric vehicles and renewable energy storage has placed significant pressure on battery manufacturers to enhance both efficiency and sustainability in their production processes. One crucial aspect of achieving this goal lies in the adoption of sustainable materials. By focusing on eco-friendly alternatives, battery factories can minimize their environmental impact while maintaining high performance standards.

The shift towards sustainable materials involves utilizing resources that are abundant and responsibly sourced. For instance, replacing traditional lithium with sodium or exploring innovative combinations of biodegradable compounds can significantly reduce the carbon footprint of battery production. Additionally, integrating recycled materials not only conserves raw resources but also supports a circular economy, where materials are reused instead of discarded. This approach not only enhances sustainability but can also lead to cost savings in the long run.

Moreover, investing in research and development of these materials is essential for driving progress in the battery industry. Collaborations between manufacturers, researchers, and environmental advocates can create a robust framework for innovation. As companies prioritize sustainable practices, they not only comply with regulatory standards but also position themselves as leaders in the transition to a greener energy future. By committing to sustainable materials, battery manufacturers can achieve efficiency gains while promoting environmental responsibility.

Data Analytics: Enhancing Decision-Making for Battery Factory Operations

In the evolving landscape of battery manufacturing, data analytics emerges as a pivotal tool to enhance decision-making processes. Given the intricacies of the lithium-ion battery production chain, which is characterized by complex interdependencies and sensitivity to various environmental factors, the implementation of robust data acquisition and management strategies is crucial. By leveraging advanced analytics, manufacturers can gain deeper insights into production efficiencies, quality control, and resource optimization, thereby streamlining operations and reducing waste.

Furthermore, the intersection of artificial intelligence and the Internet of Things is revolutionizing how battery factories operate. Predictive analytics, for instance, plays a significant role in forecasting demand and addressing supply chain challenges, ensuring that manufacturers can adapt swiftly to market fluctuations. As companies continue to innovate, integrating these technologies into their workflows not only improves operational performance but also aligns their practices with sustainability goals, promoting a balanced approach towards environmental, social, and governance (ESG) concerns within the electric vehicle ecosystem.

Battery Factory Efficiency Metrics

This bar chart displays key performance indicators for a battery factory in 2023. It highlights energy consumption, production output, waste generated, and sustainability score, providing insights into operational efficiency and environmental impact.

Renewable Energy Integration: Reducing Carbon Footprint in Battery Production

As the demand for batteries continues to soar, the urgent need for sustainable production practices becomes increasingly apparent. Integrating renewable energy sources, such as solar and wind power, into battery manufacturing processes can significantly reduce the carbon footprint of these operations. By harnessing clean energy, battery factories not only minimize their reliance on fossil fuels but also contribute to a cleaner environment. This shift towards renewables represents a critical step in making battery production more sustainable.

Moreover, incorporating innovative energy storage solutions can further enhance efficiency within battery factories. By utilizing battery systems that store excess power generated from renewable sources, manufacturers can ensure a stable and reliable energy supply, even during periods of low production. This dual approach of renewable integration and efficient energy management paves the way for a greener future in the battery industry, driving advancements in technology while aligning with global sustainability goals. As the sector evolves, it is imperative for manufacturers to prioritize these strategies to meet both economic and environmental objectives.

Innovative Solutions for Battery Factory Efficiency and Sustainability

Renewable Energy Integration: Reducing Carbon Footprint in Battery Production

| Dimension | Current Value | Target Value | Percentage Improvement |

|---|---|---|---|

| Energy Source | 60% Fossil Fuels | 30% Fossil Fuels | 50% |

| Water Usage (liters/unit) | 500 | 300 | 40% |

| Recyclable Materials (%) | 40% | 70% | 75% |

| CO2 Emissions (kg/unit) | 200 | 100 | 50% |

| Production Waste (%) | 30% | 10% | 67% |

Waste Management Innovations: Minimizing Environmental Impact in Battery Factories

In the quest for improved efficiency and sustainability in battery manufacturing, waste management innovations have emerged as a crucial focal point. Battery factories often generate significant amounts of waste during production, which can lead to a considerable environmental footprint if not managed properly. Innovative approaches such as the implementation of closed-loop recycling systems are paving the way for a more sustainable future. By recovering materials from used batteries and reintroducing them into the production cycle, manufacturers can significantly reduce the need for virgin raw materials, thus minimizing waste and conserving natural resources.

Furthermore, advancements in treatment technologies are enhancing the ability to recycle battery components effectively. Techniques such as hydrometallurgical and pyrometallurgical processes allow for the extraction of valuable metals like lithium, cobalt, and nickel from spent batteries. These methods not only contribute to reducing landfill waste but also provide a reliable source of these critical materials, which are essential for the continued growth of the renewable energy sector. As battery factories adopt these innovative waste management strategies, they not only improve their operational efficiency but also play a vital role in safeguarding the environment for future generations.

Related Posts

-

Navigating Import Export Certifications for the Leading Battery Manufacturers

-

Top Strategies for Effective Power Storage Battery Management

-

Top 15 Battery Suppliers with Industry Certification for Import Export Success

-

Future Trends in Best Lithium Ion Battery Market Analysis for 2025 Insights and Projections

-

Chinese Innovation in Best Battery Storage for a Reliable Global Future

-

Unmatched Quality of Best Lithium Ion Cells from China's Leading Manufacturers Trusted Worldwide