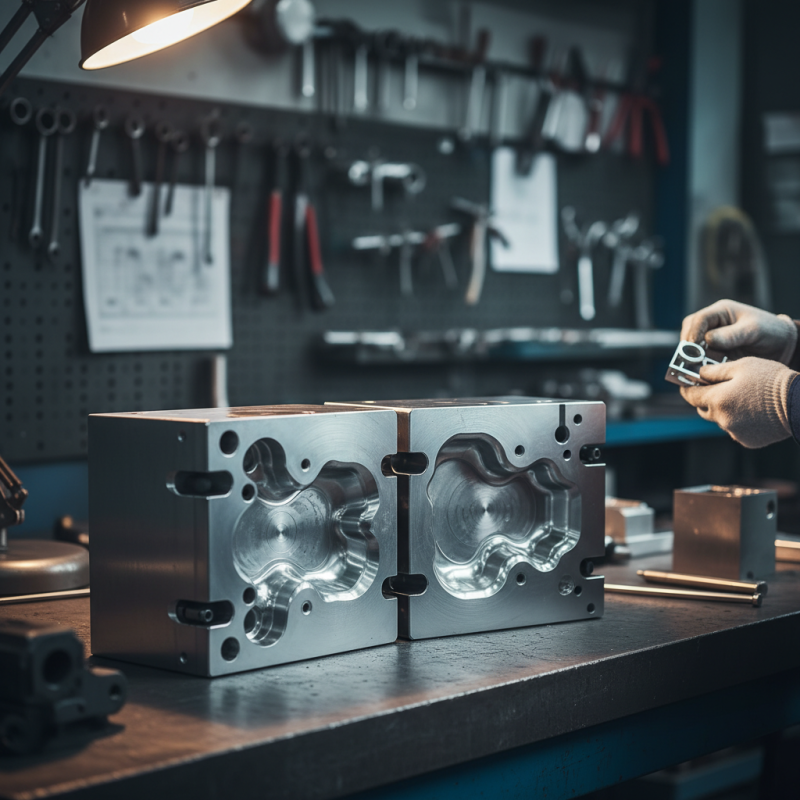

Best Die Casting Molds for Quality Production?

In the world of manufacturing, the quality of products heavily relies on the tools used in the process. Die Casting Molds play a critical role in achieving superior results. John Smith, a leading expert in die casting, states, "The mold is the heart of the die casting process." This emphasizes the importance of choosing the right molds for efficient production.

With various materials and designs available, selecting the best Die Casting Molds can be challenging. Industries often grapple with this decision. Ineffective molds can lead to defects and increased production costs. It's a dilemma many face, yet few have the perfect solution.

Investing in high-quality Die Casting Molds can yield remarkable benefits. However, the process requires careful consideration and expertise. In this competitive landscape, companies must constantly evaluate their options and strive for improvement. Only by reflecting on their choices can they hope to enhance their production quality.

Overview of Die Casting and Its Importance in Manufacturing

Die casting plays a crucial role in modern manufacturing. It allows for the production of complex shapes with high precision. According to industry reports, the global die casting market is projected to reach $80 billion by 2025. This underscores the significant demand for quality molds and efficient processes.

Molds must be designed with care. Poorly designed molds lead to defects and production issues. These can increase costs and waste. It’s essential to consider material selection and cooling channels. Optimizing these factors enhances the quality of the cast products. Many manufacturers overlook the importance of regular maintenance and inspection of molds. This can result in unexpected failures.

Tip: Always monitor the surface condition of your molds. Regular checks can prevent costly downtime.

Also, staff training is often neglected. Educating teams on die casting methods improves output quality. Continuous learning is crucial in this field. Industry data indicates that companies investing in employee training see a 30% increase in efficiency.

Tip: Document and analyze production data. This practice can reveal patterns that help mitigate issues.

Types of Die Casting Molds and Their Applications

Die casting molds come in various types, each suited for different casting needs. The most common are hot chamber and cold chamber molds. Hot chamber molds are often used for zinc and magnesium alloys. They allow for a quicker cycle time but can handle only lower melting-point metals. Cold chamber molds, on the other hand, work well with metals like aluminum. They require a more complex setup but offer better versatility for various materials.

Another significant type is the pressure die casting mold. This mold type features a pressing mechanism that forces molten metal into the mold. It's ideal for producing intricate designs with high dimensional accuracy. However, achieving this precision requires careful calibration and maintenance, which can sometimes be overlooked. Regular inspections are necessary to avoid defects. Additionally, simple construction molds may be overlooked. They’re easy to make and suitable for various products, but they may not meet the demand for high-quality finishes.

In die casting, material selection is crucial. Choosing the right material affects the mold’s lifespan and the final product's quality. Improper material choices can lead to issues like wear and deformation. This can compromise production quality and lead to rejects. Therefore, striking a balance between mold design and material properties is essential for effective production.

Factors Influencing the Quality of Die Casting Molds

Die casting molds play a crucial role in production quality. Several factors influence their effectiveness. Material selection is key. High-quality steel molds resist wear and distortion. However, not all manufacturers choose the best materials available. Many settle for less, risking reduced mold life and quality.

Precision machining is another critical factor. Molds must be crafted to exact specifications. Small errors can lead to significant defects in cast products. Some manufacturers overlook this step, leading to inconsistent results. Design complexity also contributes to the overall quality. Simplistic designs may seem cost-effective, yet they often lack the required precision.

Cooling systems within molds affect cycle times and product consistency. If cooling is uneven, defects like warping may occur. Many overlook this aspect, thinking it’s not essential. Regular maintenance and inspection are vital. Ignoring these can lead to undetected wear, impacting mold performance. Each factor intertwines, creating a delicate balance between quality and efficiency in die casting.

Best Die Casting Molds for Quality Production

Best Practices for Selecting Die Casting Molds

When selecting die casting molds, clarity on your project requirements is crucial. Focus on the material you plan to use. Different alloys may require distinct mold designs. Analyze the mold geometry, ensuring it aligns with your production goals. Complex shapes might necessitate high-precision molds. Balance between complexity and manufacturability is key.

Consider the mold's thermal conductivity. It directly impacts the cooling rate and overall cycle time. Heating and cooling efficiency can affect production quality. Also, keep in mind the durability of the mold. Wear and tear can result in increased production costs. Regular assessment of the mold’s performance is essential for long-term efficiency.

Don’t overlook the importance of mold maintenance. Without proper care, even the best molds can underperform. Establish a routine inspection schedule. It’s also wise to seek feedback from your production team. They often notice issues that the design team may miss. Being open to adjustments can lead to significant improvements. Aim for continuous learning and better practices.

Best Die Casting Molds for Quality Production? - Best Practices for Selecting Die Casting Molds

| Mold Material | Thermal Conductivity (W/m·K) | Durability (Cycles) | Cost Range ($) | Best Use Cases |

|---|---|---|---|---|

| Aluminum | 200 | 50,000 | 5,000 - 10,000 | Automotive parts, housings |

| Magnesium | 120 | 40,000 | 7,000 - 15,000 | Aerospace components, lightweight parts |

| Zinc | 80 | 30,000 | 4,000 - 8,000 | Electronics, hardware |

| Copper | 400 | 45,000 | 10,000 - 20,000 | Heat sinks, electrical components |

Maintenance and Care for Longevity of Die Casting Molds

Proper maintenance of die casting molds is crucial for extending their lifespan. Regular inspections help identify wear and tear early. Mold cooling channels should be checked for blockages. Even minor issues can lead to larger problems, affecting production quality. A simple visual check often reveals hidden cracks.

Using the right cleaning agents is essential. Harsh chemicals can damage the mold’s surface. Gentle cleaners help maintain the integrity of molds. Remember to dry molds thoroughly after cleaning. Moisture can cause rust or corrosion.

Lubrication plays a significant role too. A light coat of oil prevents parts from sticking together. This reduces wear on both the mold and the cast product. Over time, even the best molds can show signs of degradation. Keeping a maintenance log can help track problems. Regular records can guide future care decisions. By focusing on these aspects, the longevity of die casting molds can be maximized.