What is a Damper Actuator and How Does it Work?

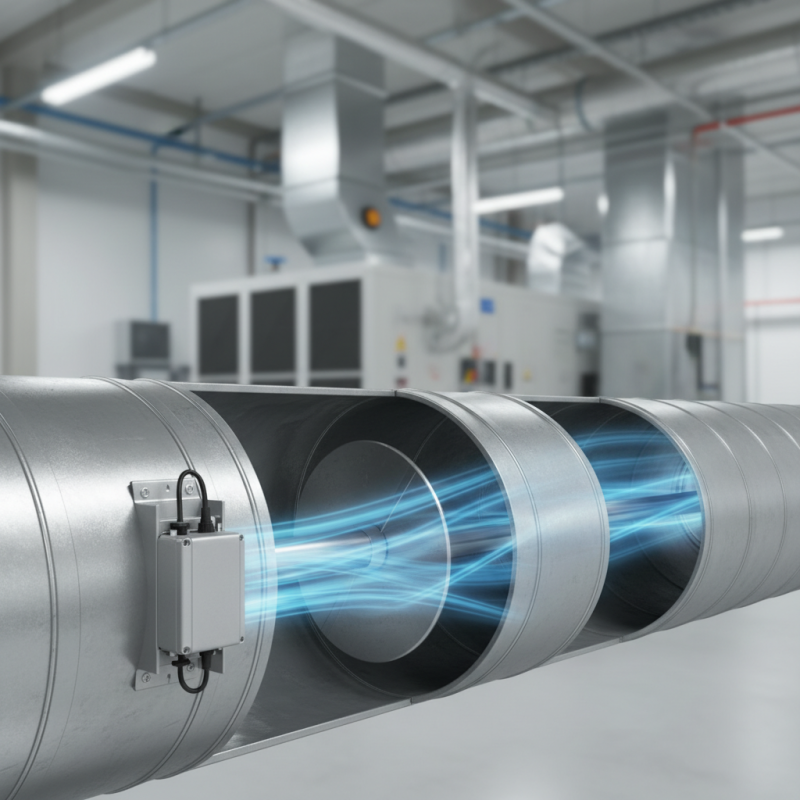

A Damper Actuator plays a crucial role in modern HVAC systems. It is responsible for controlling the flow of air and maintaining indoor air quality. According to a recent report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), proper control of airflow can enhance energy efficiency by up to 30%.

These actuators can vary in design and function. They can be pneumatic, electric, or hydraulic. Each type has unique advantages and limitations. The selection of the right damper actuator influences system performance significantly. Poor choices can lead to ineffective airflow and increased operational costs.

The HVAC industry is evolving, with innovations driving efficiency. However, many operators still overlook the potential of damper actuators. This oversight can reduce overall system effectiveness. Understanding how a damper actuator works is essential. It requires careful consideration and planning, which some engineers may not prioritize.

What is a Damper Actuator?

A damper actuator plays a crucial role in HVAC systems. It controls the flow of air within ductwork by adjusting the position of dampers. This allows for better air distribution. In turn, it enhances energy efficiency and indoor comfort. According to a report from the U.S. Department of Energy, optimizing airflow can improve energy savings by 10-30%.

These actuators can be electric or pneumatic. Electric actuators are commonly used in residential settings, while pneumatic ones often appear in commercial applications. Notably, installation errors can lead to operational inefficiencies. For example, misaligned dampers can restrict airflow, causing energy waste. It’s essential for contractors to ensure proper installation. In fact, the Air Conditioning Contractors of America found that improper damper settings can lead to decreased system performance.

Keep in mind that not all buildings utilize the same types of actuators. Factors such as building size and type dictate the appropriate choice. Some installations might even require a hybrid approach. Reviewing current system performance regularly helps identify potential issues. Proper maintenance is critical for long-lasting effectiveness. Regular checks can prevent costly repairs down the line.

Types of Damper Actuators and Their Applications

Damper actuators are essential components in HVAC systems and industrial applications. They control airflow and maintain desired temperatures. Different types of damper actuators serve various functions. Electric and pneumatic actuators are common. Each type has distinct advantages and limitations.

Electric actuators are widely used for their precision. They offer quick response times and precise control. In contrast, pneumatic actuators utilize compressed air. They are often preferred in environments where electrical components might be hazardous. However, pneumatic systems can require extensive maintenance.

There are also spring return actuators. These provide a fail-safe mechanism. If the power fails, the damper returns to a default position. This feature can enhance safety but may lead to less precise control. Each actuator type has unique benefits and potential drawbacks, depending on the specific application. Understanding these can help in selecting the right actuator for your needs.

Types of Damper Actuators and Their Applications

How Damper Actuators Operate Mechanically

Damper actuators play a vital role in regulating airflow in HVAC systems. They are responsible for opening and closing dampers, which control air distribution. According to industry reports, proper airflow management can enhance energy efficiency by 20% in commercial buildings. This makes dampers crucial for maintaining optimal indoor climates.

Mechanically, damper actuators operate through electric or pneumatic means. An electric actuator typically uses a motor to adjust the damper position. In contrast, a pneumatic actuator relies on air pressure to achieve similar results. The movement is often linear, allowing precise control of air volume. Some systems still depend on outdated mechanical designs. This can lead to inefficiencies and operational issues.

Industry data reveals that nearly 30% of HVAC systems are underperforming due to outdated technologies.

While the mechanics may seem straightforward, environmental factors complicate actuator performance. For instance, temperature changes can affect motor responsiveness. Dust and debris may also hinder damper movement. Regular maintenance is essential to ensure smooth operation. A study found that neglected actuators reduce overall HVAC efficiency by as much as 15%. These insights highlight the importance of keeping damper actuators in top shape for enhanced system performance.

Benefits of Using Damper Actuators in HVAC Systems

Damper actuators play a crucial role in HVAC systems. They control the flow of air by adjusting the position of dampers. This functionality is essential for maintaining optimal indoor air quality and comfort levels. A well-functioning damper actuator ensures that the right amount of fresh air circulates throughout a space, preventing stale air accumulation.

Using damper actuators offers several benefits. They enhance energy efficiency by optimizing airflow. When air is directed correctly, heating and cooling systems work less. This can lead to substantial energy savings over time. Moreover, precise control of air distribution helps in maintaining consistent temperatures in different areas. Some systems may struggle to achieve this balance without proper actuator control.

Even though damper actuators come with advantages, they are not without challenges. They may require regular maintenance to function effectively. Dust and debris can hinder their movement, affecting performance. Users should remain vigilant and inspect these components periodically. Addressing small issues early can prevent larger problems later.

What is a Damper Actuator and How Does it Work? - Benefits of Using Damper Actuators in HVAC Systems

| Dimension | Description |

|---|---|

| Type | Electric, Pneumatic, or Hydraulic |

| Operation Mechanism | Rotational or Linear Movement |

| Control Method | On/Off or Proportional |

| Applications | HVAC Systems, Airflow Control, Smoke Control |

| Benefits | Improved Energy Efficiency, Enhanced Comfort, Precise Control |

| Installation | Easy integration into existing systems |

| Maintenance | Regular checks recommended for optimal performance |

Common Issues and Maintenance Tips for Damper Actuators

Damper actuators play a crucial role in regulating airflow in HVAC systems. However, they can often face various issues that may impede their performance. Common problems include sticking, noise, and inconsistent operation. Sticking can occur due to dust accumulation or mechanical faults. It's vital to ensure that the actuator moves freely and is properly lubricated. Noise may indicate a misalignment or wear in the components. Regular checks can help identify these problems early.

Maintenance tips for damper actuators are straightforward but essential. Regularly inspect the actuator for signs of wear or damage. Ensure that all connections are secure and that the actuator is aligned correctly. Cleaning the actuator and its surrounding area can prevent build-up that leads to sticking. Testing the actuator's response can also reveal hidden issues. Actuators that lack proper calibration may lead to inefficiencies. Staying vigilant about these details can significantly enhance the reliability of your HVAC system.