What is a Rubber Pump Impeller and How Does It Work?

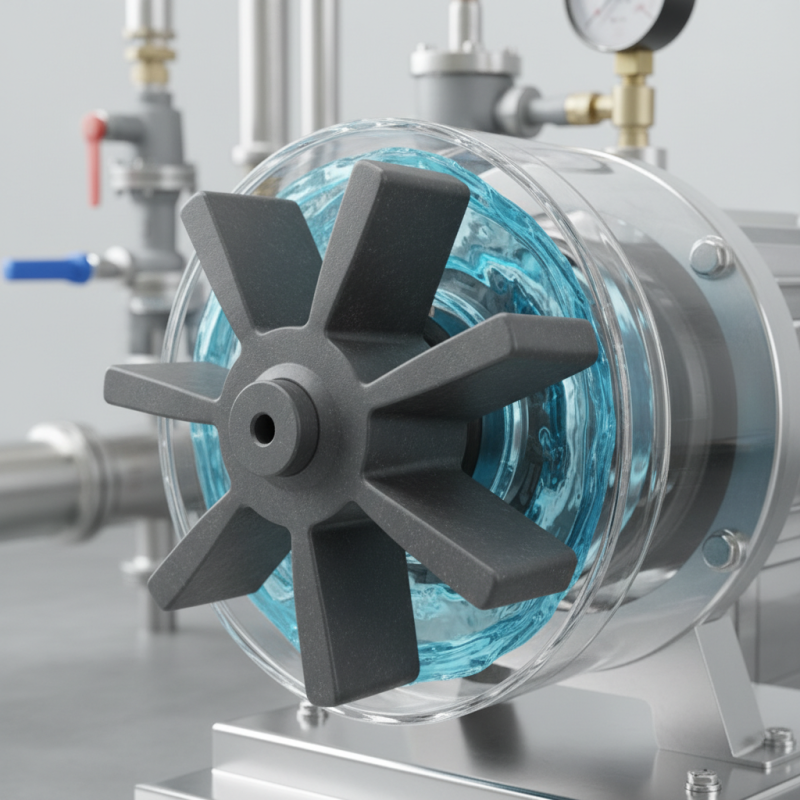

The Rubber Pump Impeller plays a critical role in various pumping systems. Its design enhances fluid flow and efficiency. Made from flexible rubber, this component can adapt to different fluids and pressures.

Understanding how a Rubber Pump Impeller works helps in recognizing its importance. When rotating, it generates centrifugal force. This action moves the liquid through the pump. The rubber material provides durability and resistance to wear. However, there are limitations to consider. Over time, the rubber can degrade and lose effectiveness.

Regular maintenance is key to ensuring optimal performance. Users often overlook this aspect. Neglecting it can lead to inefficiencies and even pump failure. Reflecting on these factors is crucial for anyone relying on this technology. The right knowledge can make a significant difference in operational success.

What is a Rubber Pump Impeller and Its Role in Fluid Dynamics?

A rubber pump impeller is crucial in fluid dynamics. Made from flexible materials, it helps move fluids efficiently. The impeller spins rapidly, creating pressure differences. This action draws fluid into the pump and pushes it out through the discharge outlet.

Rubber impellers are particularly effective in handling abrasive liquids. Their flexibility allows for some degree of wear without immediate failure. However, they can suffer from degradation over time due to chemicals or temperature changes. Observing signs of wear is essential for maintaining performance.

Tips: Regular inspection of the rubber impeller can prevent costly breakdowns. Consider the fluid’s properties when selecting materials. Sometimes, opting for a slightly stiffer impeller may enhance durability. Remember, adapting the design to specific applications can lead to better outcomes.

Rubber Pump Impeller Performance Over Different Fluid Viscosity Levels

The performance of rubber pump impellers is crucial in determining their effectiveness in various fluid dynamics applications. This bar chart showcases flow rates for a rubber pump impeller operating with different fluids at varying viscosities, highlighting the impact of fluid properties on pumping efficiency.

Key Materials Used in Manufacturing Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid transfer systems. They are primarily made from key materials such as natural rubber, synthetic rubber, and elastomers. Each material offers unique properties, affecting performance and durability. For instance, natural rubber is known for its excellent elasticity and resilience, but it may not be suitable for harsh chemical environments.

Synthetic rubbers, like nitrile and neoprene, provide better resistance to oils and chemicals. Nitrile rubber, in particular, boasts a high tensile strength and superior abrasion resistance. According to a recent industry report, synthetic rubbers account for over 65% of the global rubber market due to their versatility. These materials can withstand extreme temperatures, making them ideal for various applications in diverse industries.

However, not all materials perform equally in every situation. For example, while some elastomers excel in heat resistance, they might lack in flexibility. It’s crucial for engineers to choose the right material based on the specific operational conditions. Compromises must often be made. Understanding these material properties leads to improved designs, but challenges remain in balancing cost and performance in rubber pump impeller manufacturing.

Understanding the Design and Functionality of Rubber Impellers

Rubber impellers are essential components in various pumping systems. Their flexibility allows for a better fit within the pump casing, enhancing efficiency. The design of rubber impellers often includes multiple vanes that effectively move fluids. According to industry reports, rubber impellers can increase pump efficiency by up to 15%. This efficiency stems from their ability to handle a range of fluid types and conditions.

Functionality is another critical aspect. Rubber impellers often resist wear and provide reliable operation in harsh conditions. They can operate effectively in temperatures ranging from -30°C to 100°C. However, the material’s performance might decline under extreme thermal conditions. Industry data indicates that around 20% of failures in pumps are linked to impeller design flaws or material choices. This highlights the need for careful selection and testing during manufacturing.

Proper maintenance may also impact performance. Rubber wear can reduce efficiency over time. Regular inspections can identify signs of wear before they become critical. Inadequate checks might lead to unforeseen failures that could halt operations. Overall, understanding the design and functionality of rubber impellers is vital for optimizing performance and reliability in pumping systems.

What is a Rubber Pump Impeller and How Does It Work? - Understanding the Design and Functionality of Rubber Impellers

| Dimension | Description | Functionality |

|---|---|---|

| Material Type | Natural rubber, synthetic rubber | Provides flexibility and resistance to wear |

| Impeller Size | Varies by application, typically 2 to 10 inches | Influences flow rate and pressure output |

| Design Shape | Centrifugal, vortex, or mixed-flow | Affects efficiency and performance under varying conditions |

| Pressure Rating | Up to 150 psi, depending on design | Determines suitability for various pumping applications |

| Operating Temperature | -30°C to 100°C | Ensures functional integrity across temperature ranges |

Performance Metrics: Efficiency and Durability of Rubber Impellers

Rubber pump impellers are essential components that significantly influence pump performance. Their efficiency and durability are pivotal metrics that determine operational success. Research indicates that rubber impellers can achieve efficiency ratings up to 85% in specific applications. However, there are instances where performance dips occur. This often correlates with material degradation from wear and tear, especially in abrasive environments.

Durability is another critical aspect. According to industry reports, the average lifespan of a rubber impeller ranges from 3 to 5 years, dependent on factors like fluid type and operating conditions. Some experts suggest that regular inspections can extend this lifespan. For instance, proactive monitoring can catch early signs of damage, leading to timely replacements.

Tip: Always match the impeller material to the fluid characteristics to enhance durability. Using the wrong material can lead to premature failure and costly downtime.

Moreover, efficiency metrics can vary based on the pump design and application. Not every rubber impeller will perform equally, even in similar conditions. Some designs might struggle under heavy loads. It's crucial to evaluate and select an impeller based on specific operational demands.

Tip: Conduct performance tests in real-world conditions. This data can provide insights that may not be apparent through theoretical calculations.

Common Applications of Rubber Pump Impellers in Various Industries

Rubber pump impellers are crucial in many industries. They are used in wastewater treatment, chemical processing, and food manufacturing. These impellers provide reliable performance in challenging environments. Their flexibility and resilience make them perfect for handling abrasive and corrosive fluids.

In the water treatment sector, rubber impellers help manage sludge and other debris. They maintain efficiency while minimizing wear. In the chemical industry, they transport various fluids safely. However, the choice of rubber material is vital. Not all rubbers are suitable for every fluid. Testing is essential to avoid problems.

Tips: Always consider the fluid type when selecting an impeller. A wrong choice can lead to premature failure. Take the time to evaluate your options.

In food manufacturing, these impellers increase hygiene. They are easy to clean and do not contaminate the products. However, rubber can degrade over time if not properly maintained. Regular inspections can prevent unexpected breakdowns. Understanding these factors is key to maximizing performance.