How to Select the Best Battery Manufacturers for Optimal Energy Efficiency

In the rapidly evolving landscape of energy solutions, selecting the best battery manufacturers is pivotal for achieving optimal energy efficiency. According to a report by the International Energy Agency (IEA), global battery demand is projected to increase by over 30% per year, driven largely by the growth of electric vehicles and renewable energy storage systems. The right battery can significantly enhance performance and longevity, with high-quality lithium-ion batteries providing up to 90% energy efficiency in various applications. Additionally, research from Bloomberg New Energy Finance highlights that the cost of lithium-ion battery packs has fallen by approximately 89% since 2010, enabling more accessible deployment of cutting-edge energy solutions. Therefore, when considering energy efficiency in your projects, evaluating the credentials and technological innovations of leading battery manufacturers is essential for maximizing return on investment and sustainability goals.

Identifying Key Performance Metrics for Battery Efficiency Evaluation

When selecting battery manufacturers for optimal energy efficiency, it’s crucial to identify key performance metrics that can assess the efficiency and reliability of the batteries. One of the primary metrics is the energy density, which indicates the amount of energy stored in a given volume. According to the International Energy Agency (IEA) report, lithium-ion batteries, commonly used in electric vehicles, have an average energy density of about 250 Wh/kg, significantly higher than that of lead-acid batteries, which average around 150 Wh/kg. This higher energy density translates to longer ranges for electric vehicles and enhanced performance for various applications.

Another essential performance metric is the cycle life of batteries, which defines the number of complete charge and discharge cycles a battery can undergo before its capacity significantly degrades. A recent study released by BloombergNEF found that the lifecycle of lithium battery technology has improved dramatically, averaging around 2,000 cycles or more under standard conditions. This increase contributes to reduced total cost of ownership, making it imperative for manufacturers to provide models that not only meet these lifecycle expectations but also exhibit minimal capacity fade over time. Additionally, evaluating thermal stability and charge-discharge efficiency is vital, as these factors directly impact the safety and overall efficiency of the battery, ensuring that manufacturers meet not just performance but also safety standards.

Researching Battery Manufacturer Reputation and Experience

When selecting a battery manufacturer, researching their reputation and experience is crucial. A manufacturer's history in the industry can provide significant insights into their reliability and expertise. Companies that have been in the market for several years often have a proven track record and a multitude of customer reviews that reflect their quality and service. Examining these reviews can help potential buyers identify manufacturers with a strong commitment to energy efficiency and innovation.

Additionally, considering a manufacturer’s certifications and partnerships can shed light on their credibility. Established manufacturers often collaborate with reputable organizations or hold certifications that ensure their products meet industry standards. These affiliations can be indicative of their commitment to producing high-quality batteries that prioritize energy efficiency.

Engaging with user communities and forums may also provide third-party perspectives, further enhancing your understanding of a manufacturer’s reputation and operational excellence in battery technology.

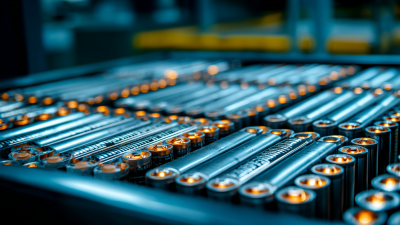

Comparing Energy Density and Charge Cycle Durability of Various Batteries

When selecting the best battery manufacturers, it's essential to focus on two key performance metrics: energy density and charge cycle durability. According to a recent report by the International Energy Agency (IEA), lithium-ion batteries typically have an energy density ranging from 150 to 250 Wh/kg, making them a popular choice for electric vehicles and portable electronics. However, advancements in battery technology, such as solid-state batteries, could push energy densities even higher, possibly reaching up to 500 Wh/kg in the next few years. This improvement not only enhances the runtime of devices but also reduces the weight of battery systems, crucial for applications requiring efficiency.

Charge cycle durability is another critical factor to consider. A study by Argonne National Laboratory highlights that while most lithium-ion batteries can endure around 500 to 1,500 charge cycles, some newer technologies boast over 3,000 cycles. Higher cycle durability translates to longer-lasting batteries, which can significantly affect the lifecycle cost and sustainability of energy storage solutions.

**Tips:** Look for manufacturers that provide detailed specifications on energy density and charge cycle longevity. Additionally, consider engaging with manufacturers who invest in R&D and follow industry advancements to ensure you’re accessing the latest technologies. Also, check for third-party certifications that can validate the performance claims of battery technologies.

Battery Energy Efficiency Comparison

Analyzing Pricing Structures and Long-term Cost Efficiency of Battery Options

When selecting the best battery manufacturers, one of the key factors to consider is their pricing structures and long-term cost efficiency. Recent industry reports indicate that lithium-ion batteries, which dominate the market, have experienced a price decline of approximately 70% over the past decade, according to BloombergNEF. This trend reflects advancements in production technologies and economies of scale, making them more accessible for consumers and businesses alike. However, it is essential to conduct a thorough analysis of the total cost of ownership, which includes not only the upfront cost but also maintenance and operational efficiency over the battery's lifespan.

**Tips:** Look for manufacturers who provide transparent pricing models that detail both initial investment and long-term operational costs. Investigate warranties and expected cycle life to assess how these factors contribute to overall savings.

Another aspect to consider is the capacity and efficiency ratings of different battery options. A high-efficiency battery may have a higher upfront cost but could lead to significant savings in operational energy costs. According to a report by Wood Mackenzie, energy storage system costs are projected to fall an additional 50% by 2030, underscoring the importance of considering future trends in pricing when selecting a manufacturer.

**Tips:** Compare performance metrics and efficiency ratings between different suppliers; a slightly higher initial price might be offset by better energy savings over time. Prioritize manufacturers that offer flexible pricing structures, as they may provide more options for financing and long-term contracts, facilitating better budget management.

Examining Environmental Standards and Sustainability Practices of Manufacturers

When selecting battery manufacturers, it's essential to examine their environmental standards and sustainability practices. The impact of battery production on the environment can be significant, involving resource extraction and waste generation. Manufacturers who prioritize sustainable practices often employ advanced recycling techniques and utilize renewable energy sources in their production processes. By choosing these manufacturers, consumers can ensure that they are supporting companies committed to minimizing their carbon footprint and promoting a circular economy.

Moreover, adherence to international environmental standards such as ISO 14001 can be a strong indicator of a manufacturer's dedication to sustainability. This certification requires continuous improvement in environmental performance, motivating manufacturers to reduce pollutants and manage waste effectively. Additionally, manufacturers that engage in transparent reporting about their environmental impact and sustainability initiatives enable potential customers to make informed decisions based on the company's ethical stance and accountability. In this way, focusing on environmental standards can guide buyers toward selecting battery manufacturers that not only meet their energy efficiency needs but also align with broader ecological goals.

How to Select the Best Battery Manufacturers for Optimal Energy Efficiency - Examining Environmental Standards and Sustainability Practices of Manufacturers

| Manufacturer Type | Energy Efficiency Rating | Recycling Programs | Sustainability Certifications | Carbon Footprint (kg CO2/kWh) |

|---|---|---|---|---|

| Lithium-ion | 95% | Yes | ISO 14001 | 0.20 |

| Nickel-Metal Hydride | 90% | Partial | RoHS Compliant | 0.25 |

| Lead-Acid | 85% | Yes | UL Certified | 0.30 |

Related Posts

-

Your Essential Guide to the Latest Innovations in Battery Technology

-

Top 15 Battery Suppliers with Industry Certification for Import Export Success

-

Navigating Import Export Certifications for the Leading Battery Manufacturers

-

How to Harness the Advantages of Best New Battery Technology for Your Business

-

Innovative Solutions for Battery Factory Efficiency and Sustainability

-

Unlocking Performance: In-Depth Technical Specifications of the Best Lithium Ion Solar Battery