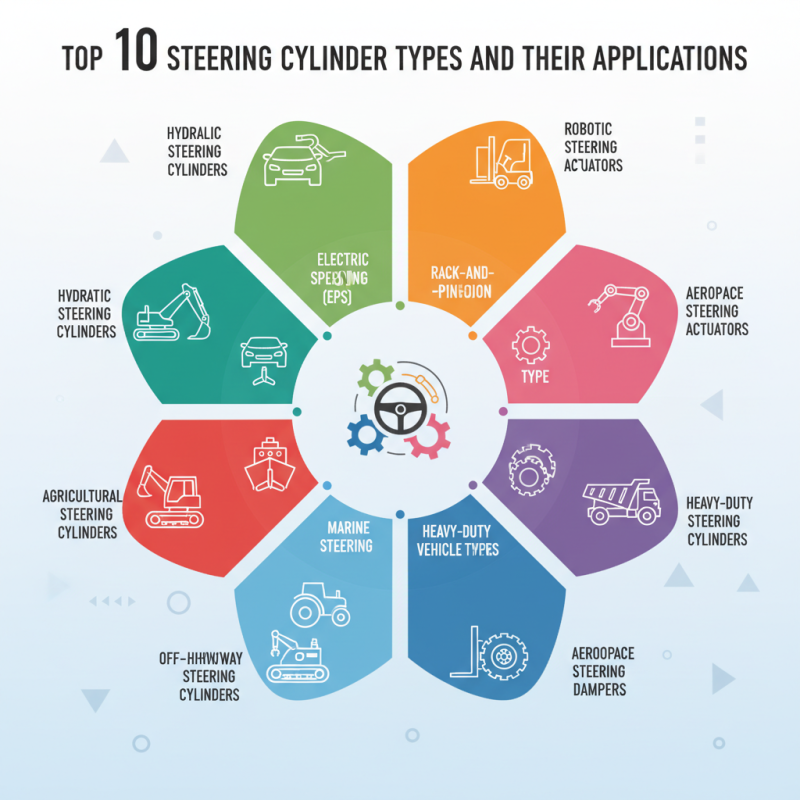

Top 10 Steering Cylinder Types and Their Applications?

Steering Cylinders are essential components in various machinery. They play a crucial role in controlling the direction and stability of vehicles and equipment. The global steering cylinder market is projected to grow significantly, with an expected CAGR of over 5% from 2023 to 2030. This demand reflects the increasing need for precision and safety in automotive and industrial applications.

Different types of steering cylinders exist to meet diverse operational needs and standards. From hydraulic systems in heavy machinery to electric steering in modern vehicles, each type serves unique functions. For instance, hydraulic steering cylinders provide superior responsiveness but may require more maintenance than electric models. Despite advancements, challenges like efficiency and durability remain critical concerns in the industry.

Understanding steering cylinder types and their applications can enhance operational effectiveness. Proper selection can impact not only performance but also longevity and safety. There is a pressing need for ongoing innovation and research to address these issues. This exploration aims to highlight the top 10 steering cylinder types, showcasing their varied applications and the importance of making informed choices.

Overview of Steering Cylinders and Their Importance in Vehicles

Steering cylinders play a crucial role in vehicle dynamics. They translate the driver's steering input into the motion of the wheels. This is critical for vehicle handling and safety. According to a recent industry report, steering cylinders can affect overall vehicle responsiveness and control by up to 30%. The materials and designs used can greatly influence these metrics.

The importance of steering cylinders is highlighted in commercial vehicles. These vehicles often rely on hydraulic-assisted systems. A survey showed that 70% of heavy-duty trucks utilize this technology for better maneuverability. However, many vehicles still use mechanical systems that can lead to increased driver fatigue and less precise handling over time. The choice of steering cylinder type can impact the vehicle's life cycle and maintenance needs.

Operational efficiency plays a significant role too. For instance, improper maintenance of steering cylinders can lead to fluid leaks and decreased performance. A report found that about 15% of steering-related failures were due to neglected maintenance in heavy machinery. Companies must prioritize regular inspections. Emerging trends show a shift towards electric power steering, but traditional systems are still prevalent. Many drivers question the reliability of these newer technologies, reflecting a need for more comprehensive testing and data.

Top 10 Steering Cylinder Types and Their Applications

| Steering Cylinder Type | Application | Operating Pressure (psi) | Key Features |

|---|---|---|---|

| Double-acting Cylinder | Commercial Trucks | 2000 - 2500 | High efficiency, robust design |

| Single-acting Cylinder | Agricultural Equipment | 1500 - 2000 | Simple design, cost-effective |

| Electric Steering Cylinder | Electric Vehicles | Varies | Energy-efficient, precise control |

| Hydraulic Steering Cylinder | Heavy Machinery | 2500 - 3000 | High strength, reliable performance |

| Pneumatic Steering Cylinder | Industrial Vehicles | 100 - 150 | Lightweight, quick response |

| Compact Steering Cylinder | Robotics | Varies | Space-saving, versatile |

| Rotary Steering Cylinder | Marine Applications | Varies | Smooth rotation, corrosion-resistant |

| Knuckle Steering Cylinder | Automotive | 2000 - 3000 | Excellent maneuverability, compact design |

| Buckle Steering Cylinder | Sports Cars | 2500 - 3500 | Enhanced performance, precision engineering |

| Integral Steering Cylinder | Large Trucks | 3000 - 4000 | High load capacity, durability |

Hydraulic Steering Cylinders: Mechanism and Applications

Hydraulic steering cylinders are vital in various applications. They provide precise steering control in vehicles and heavy machinery. These cylinders use hydraulic pressure to assist in turning, allowing for easier maneuverability. According to a report by Market Research Future, the hydraulic cylinder market is expected to reach USD 24 billion by 2025. This growth reflects the increasing demand for efficient steering systems.

In marine applications, hydraulic steering cylinders play a crucial role. Boats utilize them for streamlined handling. Feedback from operators highlights issues with responsiveness under high loads. Not all systems maintain consistent pressure, leading to potential safety concerns. Moreover, in construction, the reliance on these cylinders can pose risks. A breakdown in the hydraulic system may lead to equipment failures.

Recent studies have shown that proper maintenance can significantly enhance performance. Many operators overlook this aspect due to busy schedules. Regular checks can prevent costly repairs and improve safety. User awareness is essential. Small oversights can escalate into major problems. Investing in training for operators can make a difference.

Electronic Steering Cylinders: Features and Benefits

Electronic steering cylinders have revolutionized the way vehicles handle steering dynamics. These systems integrate advanced technology, providing precise control and better responsiveness. Unlike traditional mechanical systems, electronic cylinders enable adjustments based on real-time data. This feature enhances driving comfort significantly.

One notable benefit is the reduction in weight. Traditional systems often add unnecessary bulk. Electronic systems are compact, which can improve fuel efficiency. They also simplify installation, potentially lowering manufacturing costs. However, the reliance on electronic components may introduce vulnerabilities. These systems can face issues from electrical failures or software glitches.

Another essential aspect is adaptability. Electronic steering can adjust to different driving conditions. Whether navigating tight spaces or speeding down highways, it can modify its behavior. Yet, this adaptability requires constant calibration. Failures in maintaining optimal settings can lead to suboptimal performance. Users may overlook the importance of regular maintenance, putting reliability at risk.

Top 10 Steering Cylinder Types and Their Applications

Pneumatic Steering Cylinders: Usage in Various Industries

Pneumatic steering cylinders play a vital role in various industries. They utilize compressed air to create movement and control steering. This technology is widely adopted in manufacturing and automotive applications, among others. Notably, these cylinders offer precise steering capabilities and fast response times. However, the reliance on compressed air can lead to inefficiencies if not monitored closely.

In the construction sector, pneumatic steering cylinders are often used in heavy machinery. They provide the necessary force to maneuver large vehicles with ease. But, there can be challenges. If the air supply is inconsistent, it compromises performance. In the materials handling industry, these cylinders enhance the performance of forklifts and conveyor systems. They ensure smooth movement, but again, a failure in air pressure can create delays.

Many industries benefit from the versatility of pneumatic cylinders. They are lightweight and reduce the overall weight of machines. While they increase efficiency, maintenance must not be overlooked. Regular checks on seals and air supply are essential. Without them, even the best-designed systems can falter.

Comparative Analysis of Different Steering Cylinder Types

When analyzing steering cylinder types, understanding their applications is crucial. Hydraulic steering cylinders dominate in heavy machinery. They offer powerful maneuverability, essential for large vehicles. On the other hand, electric steering systems present a lighter option. They improve energy efficiency and reduce maintenance costs. However, users often find them less responsive at high speeds.

Pneumatic steering cylinders provide a unique advantage in specific environments. They excel in applications that require quick adjustments. Yet, their reliance on air pressure makes them less reliable in harsh conditions. Mechanical steering systems, while traditional, can be cumbersome. They lack the responsiveness of hydraulic or electric options but are simple and easy to repair.

It's important to weigh the pros and cons of each type. No one-size-fits-all solution exists. Some users find the switch to electric systems frustrating due to unfamiliar handling. Others may overlook the simplicity of mechanical systems, missing out on their reliability. Evaluating the specific demands of each application can guide the best choice for steering solutions.